Masonry & Brickwork Support System

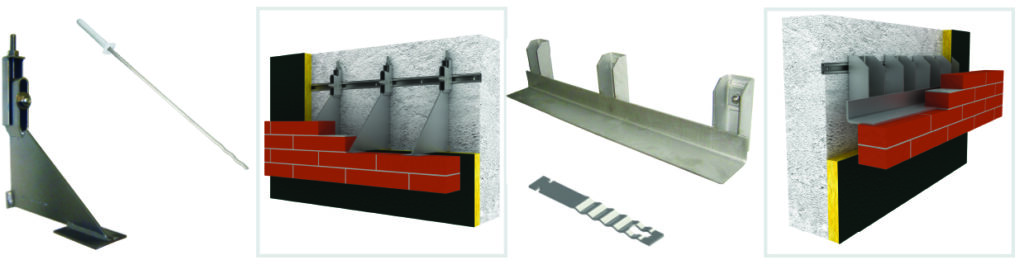

- Brickwork Support Brackets

- Brick Ties – HRST

- Masonry Support Angles

- Wall Ties – HWT – M

- Brick Tie Channels

- Windposts

- Lintels

Masonry Support & Brick Support System

Brick support & Masonry support systems are used for the secure and easy installation of brickwork facades. The brickwork brackets are used to transfer the dead loads of non-load bearing outer shell brickwork walls & masonry walls cladding to the load bearing inner walls of a building. Load-bearing masonry support brackets are fixed on concrete beams which carry the dead load of the façade.

The following points should be carefully evaluated when designing a masonry facade

- the thickness of insulation and air gap

- design of details, such as,

- wall areas,

- joints,

- external and internal corners,

- lintels above doors and windows,

- and columns.

HRST Restraints Ties or HWT-M wall ties are used along the rest of the storey height to secure the brickwork facade against wind loads.

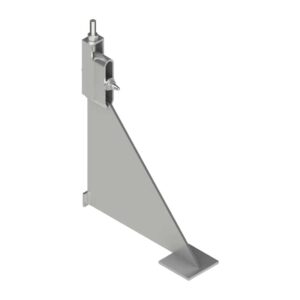

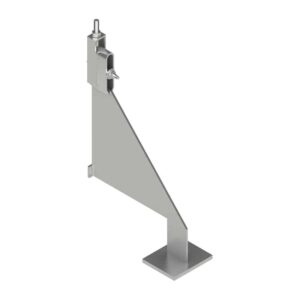

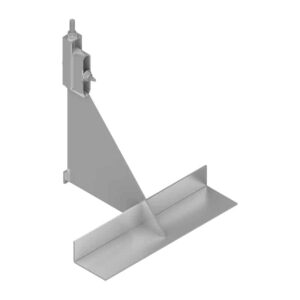

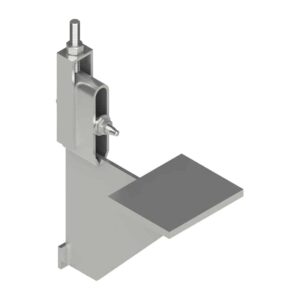

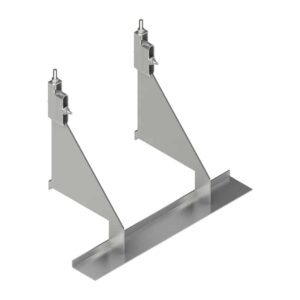

Masonry Support Brackets

A brickwork wall which is built with bricks is formed out of a load-bearing inner wall, an insulating layer and an outer wall. The outer wall cannot be used for load-bearing purposes nor can it be used for attachments of various components. The outer wall is a design element that satisfies the aesthetics and serves as a means of weather protection. The outer wall which is constructed of layers of brickwork needs to be supported at regular intervals. The load of brickwork is transferred onto the inner load-bearing wall by brickwork support brackets. Restraining of the outer wall is made with restraint wall ties. Therefore, both the inner and outer wall shells are connected to each other with load-bearing brackets and restraint wall ties.

Types of Masonry Support Brackets

The production of various types of brick support systems is available at HAZ Metal. There is a standard product range shown below. Special parts can be produced according to project requirements. Technical service is available for proposing fixing systems and the design is prepared to show all relevant details. This system can be manufactured in stainless steel grades 1.4401 (A4) & 1.4301 (A2).